Let’s be honest. When you hear “digital twin,” you probably picture a massive automotive plant or a sprawling smart city project. It feels like a tool for the giants, right? Well, here’s the deal: that perception is changing, and fast. For small-scale manufacturers and logistics operators, this once-futuristic tech is becoming a surprisingly accessible game-changer.

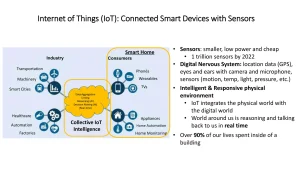

Think of a digital twin as a living, breathing digital replica. It’s not just a 3D model or a static diagram. It’s a dynamic, data-fed mirror of your physical operation—a single machine, a production line, or even your entire warehouse workflow. This virtual copy updates in real-time, letting you test, tweak, and optimize without ever touching a physical screw or rerouting a real truck. The potential for smaller players is, honestly, enormous.

Why Small-Scale Operations Can’t Afford to Ignore This

Sure, you’re agile. You can pivot quickly. But you’re also resource-tight. Every minute of downtime, every inefficient route, and every production hiccup hits harder. That’s where a pragmatic approach to digital twin integration for SMEs comes in. It’s about de-risking your operation in a hyper-competitive world.

The core value? Foresight. Instead of reacting to problems, you start predicting them. Imagine knowing a key machine will need maintenance next Thursday, not finding out when it screeches to a halt on Monday morning. Or simulating a new client’s custom order flow digitally before you commit precious floor space and materials. That’s the power we’re talking about.

Bridging the Physical-Digital Gap, Step by Step

This doesn’t require a million-dollar IT overhaul. Seriously. The key is to start small and focused. Think of it as building a map, one detail at a time.

- Start with a Single Asset or Process: Pick your most critical—or most problematic—piece of equipment. A CNC machine, a packaging station, your delivery van fleet. Model it. Connect it with simple IoT sensors for data on vibration, temperature, or GPS location.

- Focus on Data You Already Have: You’re likely sitting on goldmines of data from your ERP, inventory software, or even basic time logs. A digital twin gives that scattered data a home and a purpose, visualizing how it all interacts.

- Choose Accessible Platforms: Cloud-based digital twin solutions have dramatically lowered the barrier to entry. Look for modular platforms that scale with you, avoiding the monolithic systems designed for corporate giants.

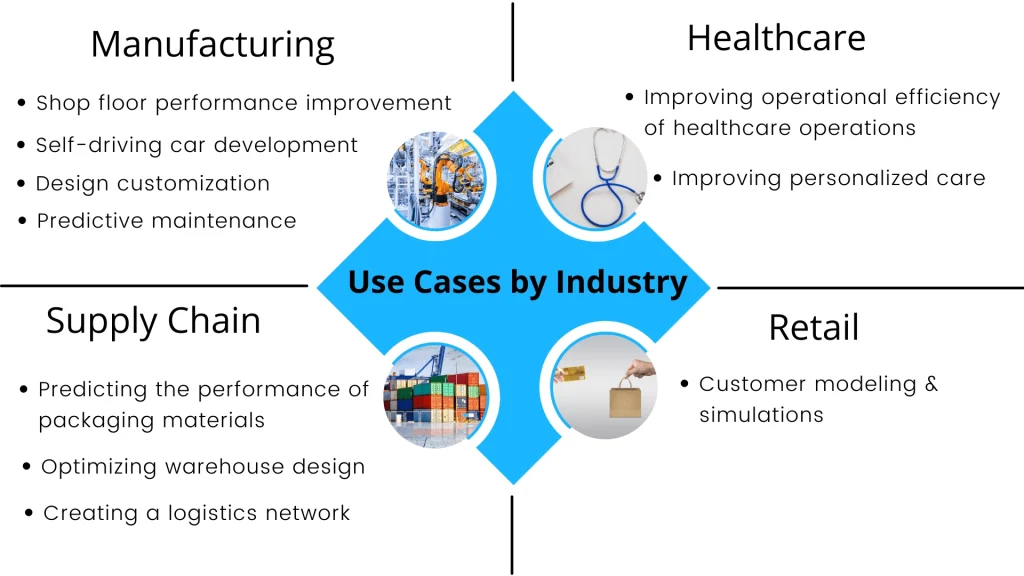

Tangible Use Cases: Where the Rubber Meets the Road

Okay, so what does this look like in practice? Let’s get specific.

1. Hyper-Efficient Production Scheduling

You get a rush order. Instead of manually figuring out if you can slot it in, you run the scenario in your digital twin of the workshop floor. The model simulates the impact on existing jobs, material flow, and machine workload. You see bottlenecks before they happen. You can accept the order with confidence or negotiate a realistic timeline—all based on a virtual dry run.

2. Logistics and Warehouse Flow Optimization

For small-scale logistics, space and time are everything. A digital twin of your warehouse layout lets you play a constant game of “what if.” What if we store the high-turnover items here? What if we reconfigure the picking path like this? Simulate new layouts digitally to find the most efficient pick-pack-ship flow before you lift a single shelf.

| Pain Point | Traditional Approach | With a Digital Twin |

| New Layout Planning | Physical rearrangement, trial & error, operational disruption. | Virtual simulation. Test 10 layouts in an afternoon with zero downtime. |

| Predicting Delivery Times | Historical averages, often inaccurate with traffic or weather. | Live traffic/weather data integrated into the twin for dynamic, accurate ETAs. |

| Maintenance | Scheduled or reactive (“run-to-failure”). | Predictive. The twin alerts you to anomalies before a breakdown occurs. |

3. Client Collaboration and Customization

This is a hidden gem. For shops doing custom or prototype work, a digital twin becomes a powerful communication tool. Instead of complex drawings, share a link to the interactive twin of the product or process. Clients can visualize it, understand constraints, and provide feedback in context. It builds trust and reduces costly misunderstandings—a huge win for small businesses.

Navigating the Real-World Hurdles

It’s not all smooth sailing, of course. The initial learning curve is a thing. And data—getting clean, consistent data—is the fuel for your twin. If your current data is messy, the twin’s insights will be messy. The trick is to start simple and let the need for better data discipline grow organically from a project you actually care about.

Cost is a valid concern, but the ROI frame has shifted. It’s not just about buying software; it’s about avoiding cost in small-scale manufacturing. Avoiding a single major machine failure, or eliminating just a few percent of wasted material, can pay for the initial investment. Think of it as insurance with a direct productivity bonus.

The Human Element: Your Team is Key

This is crucial. A digital twin isn’t a magic box that runs itself. Its success hinges on the people who use it. Involve your floor managers, your lead technicians, your logistics planners from day one. Their tacit knowledge—the “why” behind every workaround—is what makes the digital model truly accurate and useful.

Frankly, if the tool feels imposed from above, it’ll fail. But if it’s seen as a digital assistant that helps solve their daily frustrations? That’s when adoption sticks.

Looking Ahead: Not a Destination, but a Journey

Integrating a digital twin isn’t a one-and-done project. It’s more like planting a tree. You start with a seed—a single process. You nurture it with data. You watch it grow and begin to connect with other systems, slowly creating a fuller, richer digital ecosystem of your entire operation.

The end goal isn’t just a slick virtual model. It’s about building a more resilient, responsive, and intelligent business. For the small-scale manufacturer or logistics provider, that’s not just a tech upgrade. It’s a fundamental shift from working in the business to working on it—with a crystal-clear digital mirror providing the perspective you need to thrive.

More Stories

The Rise of Ambient Computing and Invisible Interfaces: When Technology Fades Into the Background

The Developer’s Guide to Post-Quantum Cryptography Implementation

Smart Home Automation for Renters: Your Guide to a Smarter, Temporary Space